Product

An overview,

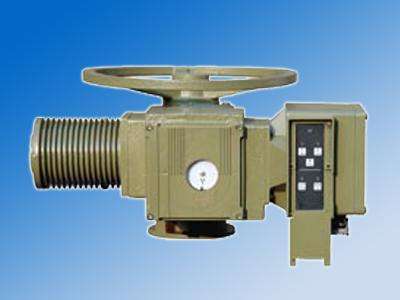

3 series angular stroke (partial rotation) electric actuator is an electromechanical device that controls the operation of the final control elements (valves, air doors, baffles) in the open-loop and closed-loop control system.

The angular stroke (partial rotation) electric actuator used in the open-loop control system is composed of 2SA30 (S series) series multi-rotation electric actuator + secondary reducer produced by Siemens technology, which is suitable for the control of butterfly valve, ball valve and other final control elements, mainly in the open and closed positions.

The angular stroke (partial slewing) electric actuator used in the closed-loop control system is composed of 2SA35 (R series) series multi-slewing electric actuator + secondary reducer manufactured with Siemens technology, which is suitable for controlling various control valves.

Ii. Environmental conditions

1. Ambient temperature: S series :-20 ~ +8O℃

R series: -20 ~ +60℃

2. Relative humidity: ≤90% (25℃)

3. No corrosive or explosive gases

4. No strong vibration

Iii. Check and proofread Siemens electric actuator

In general, electric actuators do not require maintenance (except for the connection of the output thrust to be wetted regularly), and a routine inspection is usually conducted every 3 months to determine:

1. Whether it conforms to the specified technical parameters

2. Whether the operation of the electric actuator is normal (such as vibration, noise, etc.)

3. Whether fastening parts (such as bolts) are loose

4. Is there any oil leakage

The above is only routine inspection. If further inspection is needed, it must be carried out under specific system conditions. The problems and deviations found in the inspection should be corrected immediately. The overall inspection of the actuator should be carried out when replacing the lubricating oil in the reducer, and the unit with the inspection ability should undertake this work.

Iv. Maintenance of Siemens multi-turn electric actuator

Before the maintenance of the electric actuator, necessary safety measures should be taken to ensure the safety of the maintenance. In the maintenance process, the main circuit and each branch should be cut off the power supply, and remove the cable on the actuator, live parts around should be isolated.

Bell solemnly promise: the products have been through strict quality control operations and performance tests before leaving the factory, from now on in normal use conditions warranty for one year. However, the warranty does not cover disasters beyond human power, external damage, or disassembling without our consent.